Hudds

New member

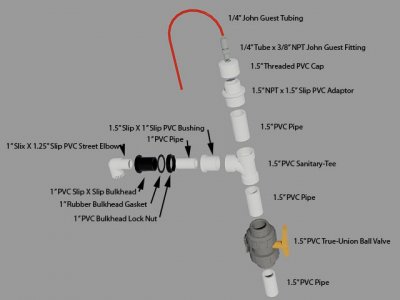

Again, a 1.5" pipe is more than sufficient for the flow rate in question. Increasing the size and capacity is pointless and will only make the siphon harder to start and require the valve to be almost fully closed to maintain balanced flow.

Return plumbing should be sized as large as reasonably possible, but for the pumps and flow rates in context, anything over maybe 1.5" will not yield any great benefit.

Respectfully, there are hundreds (if not thousands) of folks using this system "as published" with returns pumps similar to what you will be using. Don't complicate your setup by trying to change the parameters when such changes are not needed.

Many thanks :thumbsup: