You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silent and Failsafe Overflow System

- Thread starter JohnL

- Start date

jfuka78

New member

Is 1/4 " glass suffice for coast to coast? Figure there is no weight since inside tank.

Going to go with 1.5" pipe bulk heads. So figuring a box 5" deep and 6" tall

This will leave me an 1" of clearance on the top for making waves and 1/2" under the 1.5" 90

This is for a 180

Going to go with 1.5" pipe bulk heads. So figuring a box 5" deep and 6" tall

This will leave me an 1" of clearance on the top for making waves and 1/2" under the 1.5" 90

This is for a 180

Is there a recommended single source to purchase all of the items on Bean's part list? I understand that you may not need a few of the parts but I'm just looking to plug in the parts, increase quantity to 3, and pay  I was at the local hardware store and they didn't have some items, then I went to another and they didn't have something else. When it was all said and done I just said forget it. Has to be a place on-line to buy this...

I was at the local hardware store and they didn't have some items, then I went to another and they didn't have something else. When it was all said and done I just said forget it. Has to be a place on-line to buy this...

The problem when I looked at say Bulk they may call something totally different than what is on his (Bean's) part list. This is when ignorance hurts I picked up 2 40 breeders to try this on. Figured once I'm done I can later replicate it on a 100 to 300 gallon when I'm ready for that. For now all I need to do is consolidate my two 29 gallon biocubes and I've been dying to try this out.

I picked up 2 40 breeders to try this on. Figured once I'm done I can later replicate it on a 100 to 300 gallon when I'm ready for that. For now all I need to do is consolidate my two 29 gallon biocubes and I've been dying to try this out.

Thanks.

The problem when I looked at say Bulk they may call something totally different than what is on his (Bean's) part list. This is when ignorance hurts

Thanks.

uncleof6

Active member

The only parts you should HAVE to find a source for are the sanitary tees, which are made by Charlotte Pipe & Foundry, and if you want higher quality, real JG fittings ("air vent" parts,) this is the place for them: http://www.h2odistributors.com/fittings-kits-and-tubing.asp ; quality valves also require an alternate source. Other than that, the parts (you don't need to use sanitary tees, and abs will work,) including valves, "knock off" JG type fittings, are common to any WELL stocked big box or plumbing/irrigation supply. Unfortunately, other than my storage facility, and garage, you won't find 100% of the parts in one place. (No, I don't sell parts.)

Last edited:

The only parts you should HAVE to find a source for are the sanitary tees, which are made by Charlotte Pipe & Foundry, and if you want higher quality, real JG fittings ("air vent" parts,) this is the place for them: http://www.h2odistributors.com/fittings-kits-and-tubing.asp ; quality valves also require an alternate source. Other than that, the parts (you don't need to use sanitary tees, and abs will work,) including valves, "knock off" JG type fittings, are common to any WELL stocked big box or plumbing/irrigation supply. Unfortunately, other than my storage facility, and garage, you won't find 100% of the parts in one place. (No, I don't sell parts.)

The parts bin / sell made me giggle. No, I would assume that but I'd wager you have been asked before. Many thanks. I really appreciate the help.

Just sent off a order for some LED's. Plumbing is next on the list. Then off to the lumber yard to build a stand to set these on. Thank you again!

Ok......... Question.... My BeanAnimal overflow has been working silent and flawless til up to last night when I could here the small tube causing the suction sound activating the open channel. Doesnt seem to matter what I do to adjust the valve on the full siphon stand pipe it keeps like pulsing filling up then purging down the Open channel. I would assume something has to be blocking the way inside or restricting the full siphon pipe. I havent had the chance to pull it all apart or anything. But if I block flow to the open channel it goes to the overflow of the emergency channel. Makes no sense if there isnt a blockage in the primary drain. What all can cause these issues I need to check or look for? Thanks ahead of time for any assistance.

Did your return pump start pushing more water?

Not that I know of. Im using 1.5 inch drain should be able to well over handle more then the Laguna 2000 im using.

tassod

New member

Issues with my BA setup

Issues with my BA setup

Hello all,

I'm having some problems with my bean animal overflow that i'm hoping someone can shed some light on. I finished my build a few weeks ago and initially it seemed fine although it still might not be working as designed.

Issue i am having now has been happening since i added 2 reactors that are fed from my return pump and a UV which is also fed from the return. Ever since i added those, i cannot get the system balanced. My tank is a 240g with a 36" coast to coast overflow and 3 1.5" drains. My return is a hammerhead pump with (4) 1.5" return going up and over the tank manifold style. System is either pulling to much in the return chamber causing a cascade waterfall and causing my ATO to go nuts or if I cut back on the return with a valve, then the drains kick and the water level in the overflow gets sucked down completely.

The only way i have it semi stable right now is the full siphon pipe is totally closed, the open channel is basically working as full siphon since the air line tube is submerged and this is the other problem I've always had. Unless i submerge the airline tube, it will keep making noise like crazy sucking in air and creating a whole bunch of bubbles in the sump. If it is submerged, all that goes away.

I'm posting some videos and pics of my tank and maybe someone can tell me whats wrong.

Video of overflow right now:

http://s1273.photobucket.com/user/tassod/media/IMG_1470_zpsc0463047.mp4.html

Video of return section in sump:

http://s1273.photobucket.com/user/tassod/media/IMG_1469_zpsb3747236.mp4.html

Pictures of setup:

Is my return to strong? Why does the overflow pick up speed when i cut back the flow on the return? Why does the airline make that noise sucking in air when not submerged, was it not designed as a fail safe and not supposed to be submerged?

Issues with my BA setup

Hello all,

I'm having some problems with my bean animal overflow that i'm hoping someone can shed some light on. I finished my build a few weeks ago and initially it seemed fine although it still might not be working as designed.

Issue i am having now has been happening since i added 2 reactors that are fed from my return pump and a UV which is also fed from the return. Ever since i added those, i cannot get the system balanced. My tank is a 240g with a 36" coast to coast overflow and 3 1.5" drains. My return is a hammerhead pump with (4) 1.5" return going up and over the tank manifold style. System is either pulling to much in the return chamber causing a cascade waterfall and causing my ATO to go nuts or if I cut back on the return with a valve, then the drains kick and the water level in the overflow gets sucked down completely.

The only way i have it semi stable right now is the full siphon pipe is totally closed, the open channel is basically working as full siphon since the air line tube is submerged and this is the other problem I've always had. Unless i submerge the airline tube, it will keep making noise like crazy sucking in air and creating a whole bunch of bubbles in the sump. If it is submerged, all that goes away.

I'm posting some videos and pics of my tank and maybe someone can tell me whats wrong.

Video of overflow right now:

http://s1273.photobucket.com/user/tassod/media/IMG_1470_zpsc0463047.mp4.html

Video of return section in sump:

http://s1273.photobucket.com/user/tassod/media/IMG_1469_zpsb3747236.mp4.html

Pictures of setup:

Is my return to strong? Why does the overflow pick up speed when i cut back the flow on the return? Why does the airline make that noise sucking in air when not submerged, was it not designed as a fail safe and not supposed to be submerged?

Last edited by a moderator:

uncleof6

Active member

First, a little course in fluid dynamics. Flow through the drains will always equal flow from the return pump, or it will be less than the flow from the pump, in which case the tank will overflow (dry emergency kick in whichever.) So flow through the drains will not pick up speed when you reduce the flow from the pump, rather it will decrease. It (drain(s)) may handle the reduced flow better, than the higher flow, but that is to be expected when dealing with a durso, with too much flow running through it.

In terms of what the single siphon can handle, assuming your drop is around 3' would be ~ above 4000gph, but it will be less than ~4500 gph, (allowing for friction losses, and assuming you have 1.5" bulkheads, albeit they are sch 80, which is not really a good thing.) Head on the pump is probably around 4' probably, total dynamic head ~ 7 - 9' since you went a little overboard with extra pipe and fittings, to run 6 or 7 outlets (in tank, reactors, etc.) So optomistically, you are probably flowing ~ 4800 gph wide open, less what goes elsewhere than the tank. Since 2400 gph would be reasonable going through the tank, you have some room to play a bit.

You will find the solution to your drain issues throughout this thread. They are finite in number. Usually, implementation errors, and out of adjustment.

The noise in the open channel, is due to way too much flow through it. Obviously, since you have the siphon shut off right now, that is to be expected. The open channel is going to be a problem as soon as the pipe is over 1/4 full of water, which occurs in 1.5" pipe right around 350gph. When the system is adjusted right, the flow through the open channel may vary from system to system. To put a number on it, well... < 200gph in this particular system.

On your system:

The siphon is not implemented very well, as it looks like it goes horizontal just below the tank. This is in the hit list top 5. The configuration of the other two lines is random; ideally all three should be configured as near to identically as possible. (an argument against spreading the bulkheads so far apart...) Right now, the one that will have the hardest time starting is the siphon, and that is not good.

If you have air bubbles in the open channel, when the air vent line inlet is submerged, you have an air leak in the open channel. The air vent trips the open channel to siphon, when the water level continues to rise after the dry emergency kicks in. If it trips any sooner than that, the siphon will not start, as the open channel will rob flow from the siphon, causing the siphon to not fully start. Therefore, with the siphon closed (as it is now) the dry emergency should be taking the flow, not the open channel. This is how the system is intended to operate. Cause: air vent line to deep in the overlfow...

If the dry emergency is not handling the flow from the pump on its own, and is sending a large amount down the open channel, then yes you need to turn down the pump. Think about it for a moment, the dry emergency flow capacity is higher than the siphon, becuase it is not restricted.

The hammerhead is way too much pump for this system (Did I really just say that?!?) I would re-configure the pump to the Barracuda, fix the issues with the drain setup, and go back through the initial start up and adjustment procedure outlined on page 1 of the original thread, or on bean's website.

In addition, I would also increase the pump intake pipe size, and the outlet pipe size, to 2", eliminate 3 of the 4 return outlets in the tank (waste; it is the job of the powerheads to move the water around the tank) eliminate the uv sterilizer, (not much use in a reef system, as they kill food...) But these things are a bit out of the scope of your questions.

In terms of what the single siphon can handle, assuming your drop is around 3' would be ~ above 4000gph, but it will be less than ~4500 gph, (allowing for friction losses, and assuming you have 1.5" bulkheads, albeit they are sch 80, which is not really a good thing.) Head on the pump is probably around 4' probably, total dynamic head ~ 7 - 9' since you went a little overboard with extra pipe and fittings, to run 6 or 7 outlets (in tank, reactors, etc.) So optomistically, you are probably flowing ~ 4800 gph wide open, less what goes elsewhere than the tank. Since 2400 gph would be reasonable going through the tank, you have some room to play a bit.

You will find the solution to your drain issues throughout this thread. They are finite in number. Usually, implementation errors, and out of adjustment.

The noise in the open channel, is due to way too much flow through it. Obviously, since you have the siphon shut off right now, that is to be expected. The open channel is going to be a problem as soon as the pipe is over 1/4 full of water, which occurs in 1.5" pipe right around 350gph. When the system is adjusted right, the flow through the open channel may vary from system to system. To put a number on it, well... < 200gph in this particular system.

On your system:

The siphon is not implemented very well, as it looks like it goes horizontal just below the tank. This is in the hit list top 5. The configuration of the other two lines is random; ideally all three should be configured as near to identically as possible. (an argument against spreading the bulkheads so far apart...) Right now, the one that will have the hardest time starting is the siphon, and that is not good.

If you have air bubbles in the open channel, when the air vent line inlet is submerged, you have an air leak in the open channel. The air vent trips the open channel to siphon, when the water level continues to rise after the dry emergency kicks in. If it trips any sooner than that, the siphon will not start, as the open channel will rob flow from the siphon, causing the siphon to not fully start. Therefore, with the siphon closed (as it is now) the dry emergency should be taking the flow, not the open channel. This is how the system is intended to operate. Cause: air vent line to deep in the overlfow...

If the dry emergency is not handling the flow from the pump on its own, and is sending a large amount down the open channel, then yes you need to turn down the pump. Think about it for a moment, the dry emergency flow capacity is higher than the siphon, becuase it is not restricted.

The hammerhead is way too much pump for this system (Did I really just say that?!?) I would re-configure the pump to the Barracuda, fix the issues with the drain setup, and go back through the initial start up and adjustment procedure outlined on page 1 of the original thread, or on bean's website.

In addition, I would also increase the pump intake pipe size, and the outlet pipe size, to 2", eliminate 3 of the 4 return outlets in the tank (waste; it is the job of the powerheads to move the water around the tank) eliminate the uv sterilizer, (not much use in a reef system, as they kill food...) But these things are a bit out of the scope of your questions.

Last edited:

tassod

New member

On your system:

The siphon is not implemented very well, as it looks like it goes horizontal just below the tank. This is in the hit list top 5. The configuration of the other two lines is random; ideally all three should be configured as near to identically as possible. (an argument against spreading the bulkheads so far apart...) Right now, the one that will have the hardest time starting is the siphon, and that is not good. - I understand this, but nothing really i can do about it as the tank builder messed up and spread these to far apart

If you have air bubbles in the open channel, when the air vent line inlet is submerged, you have an air leak in the open channel. The air vent trips the open channel to siphon, when the water level continues to rise after the dry emergency kicks in. If it trips any sooner than that, the siphon will not start, as the open channel will rob flow from the siphon, causing the siphon to not fully start. Therefore, with the siphon closed (as it is now) the dry emergency should be taking the flow, not the open channel. This is how the system is intended to operate. Cause: air vent line to deep in the overlfow...

I only have air bubbles in the open channel when the the air line IS NOT submerged. When it is, there are no bubbles at all. As far as the emergency goes, it never gets tripped because the open channel is handling it all right now. I am confused because the more i valve back the return pump, the more the water in the overflow goes down to the point of the drains starting to suck in air.

If the dry emergency is not handling the flow from the pump on its own, and is sending a large amount down the open channel, then yes you need to turn down the pump. Think about it for a moment, the dry emergency flow capacity is higher than the siphon, becuase it is not restricted.

The hammerhead is way too much pump for this system (Did I really just say that?!?) I would re-configure the pump to the Barracuda, fix the issues with the drain setup, and go back through the initial start up and adjustment procedure outlined on page 1 of the original thread, or on bean's website.

I'll configure it to the Barracuda and try adjusting the system again.

uncleof6

Active member

I understand this, but nothing really i can do about it as the tank builder messed up and spread these to far apart.

Yes there is something you can do about it.

I only have air bubbles in the open channel when the the air line IS NOT submerged. When it is, there are no bubbles at all. As far as the emergency goes, it never gets tripped because the open channel is handling it all right now.

Ok. You have air bubbles in the open channel, because there is too much water flowing in it. The rest would apply to normal operation.

I am confused because the more i valve back the return pump, the more the water in the overflow goes down to the point of the drains starting to suck in air.

Water out will always equal water in. (It may go over the sides, but it will still be equal.) Water out cannot be greater than water in, it is not possible according to the laws of physics, as we currently understand them.

What is happening is as you lower the flow rate into the tank, the water level in the overflow drops, of course. The flow through the drain does not increase, however, it decreases; the capacity of the drain remains constant. It is a rather fine line, but it only appears to be draining faster. Yes, it can cause one to scratch their head sometimes.

X gallons per hour flows into the tank, X gph flows into the over flow, and X gph goes down the drain. Reducing the flow into the tank, X-Y gph, X-Y flows into the tank, X-Y flows into the overflow, X-Y goes down the drain.

X-Y=Z, it cannot be X-Y=X or X-Y=X+Y. Why? Because X-Y is all the water that is entering the overflow.

The drain line needs to be restricted more, because less water is flowing through it (lowers the capacity,) to raise the water level. Since there is no restriction in the line, (valve,) there is no way to raise it. This is the reason there is a valve in the siphon line, to control the water level in the overflow, raising it to the point that water just flows in the open channel.

tassod

New member

I've implemented some suggestions and it now is working as designed. First, i downgraded pump to Barracuda but i still needed to cut back on the return. Shutting it down though and starting up over again did the trick as the siphon got going. Now i have no sound from the open channel and the airline is not submerged. It is actually very quiet now and the flow of course is a lot less now going through the sump from the video i posted before but my system now is stable. To switch the full siphon with the emergency will require some more plumbing but i will see if i can get around to it but it seems to be working fine now. I was actually going to use that one as the full siphon but realized that the full siphon hole int the overflow is about 1/4" lower than the other ones which is something i requested to be done...just wish he didn't put that whole so far apart. Thanks for your help though, i do understand how it works now!

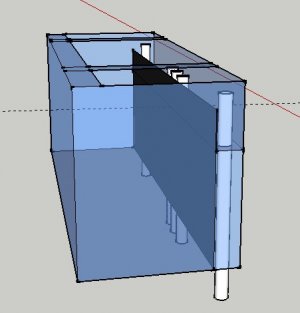

Hi all, I'm trying to design my first marine aquarium, and have been reading through this thread for the last couple of days.

I have read about disadvantages and advantages of both internal and external overflow boxes and have now gained a fairly good idea.

My main concern about all designs is that holes need to be cut in the main back glass for an internal overflow and that a horizontal cut has to be done for an external one.

Due to the above, I tried to think about a design where the cuts on the back glass are minimized (as I'm over obsessed about the idea of weakening the tank).

Can you pls let me know your views in regards to the below design?

I tried to avoid touching the back glass.. which will act as a full coast-to-coast, the return pipes will be on the sides and pass over the back glass to the sides...

Shall I continue to work on this idea?

I have read about disadvantages and advantages of both internal and external overflow boxes and have now gained a fairly good idea.

My main concern about all designs is that holes need to be cut in the main back glass for an internal overflow and that a horizontal cut has to be done for an external one.

Due to the above, I tried to think about a design where the cuts on the back glass are minimized (as I'm over obsessed about the idea of weakening the tank).

Can you pls let me know your views in regards to the below design?

I tried to avoid touching the back glass.. which will act as a full coast-to-coast, the return pipes will be on the sides and pass over the back glass to the sides...

Shall I continue to work on this idea?

Attachments

Has anyone had issues with their system starting back up after return pump is off? My "full siphon" never starts back up so then my partial siphon ends up making all kinds of noise every 30 seconds or so when the water level rises and it clears the overflow quickly. I can see air trapped in the PVC if I look up unto the PVC.

I put tubing in there and sucked the air out and that seems to fix it, but I shouldnt have to do this...Its run fine for 6 months with no issues and now this happens anytime there is a power failure/return pump maintenance etc.

Thoughts?

I put tubing in there and sucked the air out and that seems to fix it, but I shouldnt have to do this...Its run fine for 6 months with no issues and now this happens anytime there is a power failure/return pump maintenance etc.

Thoughts?

woodnaquanut

Active member

Has anyone had issues with their system starting back up after return pump is off? My "full siphon" never starts back up so then my partial siphon ends up making all kinds of noise every 30 seconds or so when the water level rises and it clears the overflow quickly. I can see air trapped in the PVC if I look up unto the PVC.

I put tubing in there and sucked the air out and that seems to fix it, but I shouldnt have to do this...Its run fine for 6 months with no issues and now this happens anytime there is a power failure/return pump maintenance etc.

Thoughts?

You might want to look back thru the thread for suggestions. Pics are good too.

Two common issues that prevent startup:

Having the siphon line too deep in the sump. It should be only about 1 inch deep at normal sump running level.

Horizontal runs on the siphon line will also cause issues.

These are just guesses. Pics are really useful for a better diagnosis.

asudavew

Active member

Has anyone had issues with their system starting back up after return pump is off? My "full siphon" never starts back up so then my partial siphon ends up making all kinds of noise every 30 seconds or so when the water level rises and it clears the overflow quickly. I can see air trapped in the PVC if I look up unto the PVC.

I put tubing in there and sucked the air out and that seems to fix it, but I shouldnt have to do this...Its run fine for 6 months with no issues and now this happens anytime there is a power failure/return pump maintenance etc.

Thoughts?

Has your water level changed in your sump? Possibly deeper?

Jimbojames

New member

got my bean animal up, i seem to have noise, sound of water going down pvc. WHY???

Similar threads

- Replies

- 3

- Views

- 171

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 801