805reef

New member

Hello, I think I have come up with my plan for my new build but was hoping to run it by you guys for reassurance.

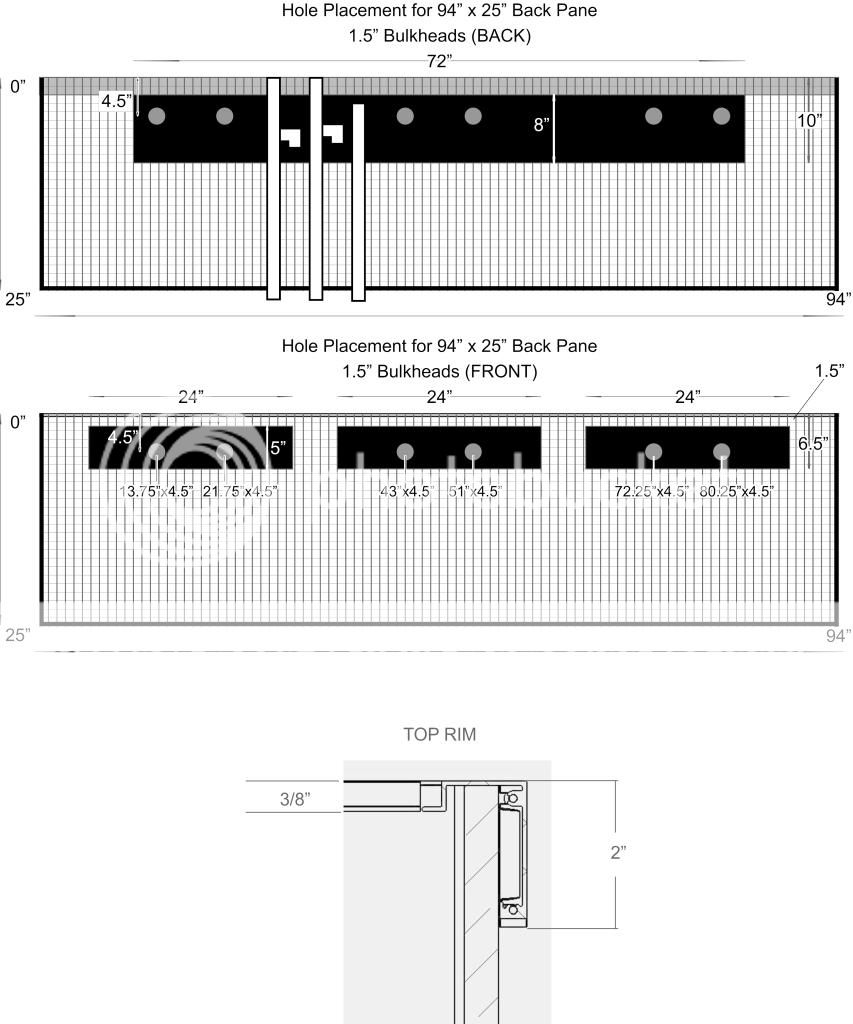

My tank will be 80x36x24 (~300 gallons) peninsula style with a full length 36" coast to coast external toothless overflow. I am planning (4) 1.5" holes be drilled into the bottom of the external overflow 2 3/8" apart (edge to edge). 3 of the holes will be for the bean system and the 4th will be for my return.

I will be using my Fluval SP4 as the return pump. I have a couple options here. I am planning on having the drain side of my sump directly under the overflow so that the 3 overflow pipes go straight down, which means the return side of the sump will be a 60" horizontal run. The total head height will be about 6'. I could either keep the return pump in the sump that way or run it external and have the return pump directly under the overflow also, so I can eliminate the additional 60" horizontal run and a couple 90s.

The reason I feel that is an important decision to make is because according to fluval at 5'9" head height the pump gives 1281gph, 7'2" 1235, 9'5" 805. Should I stick with 1.5" bulkheads or would make it as designed with 1" bulkheads?

The pump has 1" input/output connectors but I plan on running the output at 1.5" to keep all the plumbing from/to the overflow box the same and also for less friction loss. If I run the pump external would I need to up the input side to 1.5" also or could that stay at 1"?

Do you see any huge mistakes or have any suggestions for me? Thanks!

My tank will be 80x36x24 (~300 gallons) peninsula style with a full length 36" coast to coast external toothless overflow. I am planning (4) 1.5" holes be drilled into the bottom of the external overflow 2 3/8" apart (edge to edge). 3 of the holes will be for the bean system and the 4th will be for my return.

I will be using my Fluval SP4 as the return pump. I have a couple options here. I am planning on having the drain side of my sump directly under the overflow so that the 3 overflow pipes go straight down, which means the return side of the sump will be a 60" horizontal run. The total head height will be about 6'. I could either keep the return pump in the sump that way or run it external and have the return pump directly under the overflow also, so I can eliminate the additional 60" horizontal run and a couple 90s.

The reason I feel that is an important decision to make is because according to fluval at 5'9" head height the pump gives 1281gph, 7'2" 1235, 9'5" 805. Should I stick with 1.5" bulkheads or would make it as designed with 1" bulkheads?

The pump has 1" input/output connectors but I plan on running the output at 1.5" to keep all the plumbing from/to the overflow box the same and also for less friction loss. If I run the pump external would I need to up the input side to 1.5" also or could that stay at 1"?

Do you see any huge mistakes or have any suggestions for me? Thanks!