BeanAnimal

Premium Member

Wherever it is convenient within the last 2' or so of pipe

Actually, you can now disregard the question on the use of the open standpipe for my refugium. After drawing things out of on paper, I realize that it would not work quietly because the refugium is going to be in the front of my sump. Thanks anyway.

Dude, you don't have to be like that. I was just asking some simple questions to BeanAnimal.

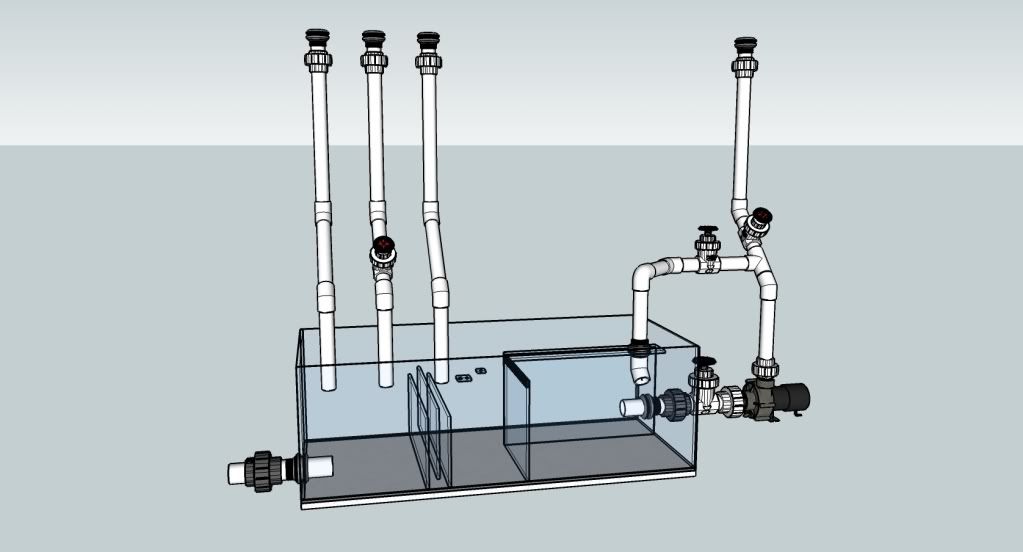

Yeah, after I was drawing everything out yesterday evening, I will more than like have to do what you have done in your diagram. I really wanted to be able to use some of the water coming straight from the overflow to the refugium, but I don't think it's going to be possible. Have you or are you going to use that many gate valves? I've heard that they usually leak after a while of use is why I ask.

I don't use a gate between the pump and sump. Just have not scaled a ball valve yet. I hear that about gate valves also, but have not found any basis for the claims yet. Then, I don't use "inexpensive" gate valves either.

Jim

All of the gate valves I ordered from AquaticEco leak at the stems after a year of infrequent use. I have nopt take the time to tear one apart and look at it or atry to fix it.

I was told early on as a noob, to use sch 80 valves and unions, because they had better seals... this is not always the case however. It seems the word 'viton' has been lost somewhere.

Jim

You are correct. In this hobby many things are just not true, and this is one of them, in fact using sched 80 valves is also throwing all flow numbers out of the window due to the reduction in the bore, some as much as 20%.

sayn3ver;15990818i was thinking of using 1" bulkheads and 1" drains. my return wil be 3/4". I am looking for somewhere between 200-300gph turnover said:4 holes if you want the return to come through the back of the tank as well. You could also take the return overt the top and use an Oceans Motions "squirt" to create a 2 or 4 port wave maker as the return.

Yes, you could put the bulkheads in a vertical alignment. Siphon on the bottom, open channel in the middle and emergency on the top. I don't have time to draw it out in CAD right now but could may be able to in the n ext 24 hours.

You are correct. In this hobby many things are just not true, and this is one of them, in fact using sched 80 valves is also throwing all flow numbers out of the window due to the reduction in the bore, some as much as 20%.

Short answer, no... Long answer maybe to yes, but thing can get complicated. The size of the combined section is very critical as, it will NOT be under a fill siphon but will have to be able to to carry the full flow of the return pump without being under siphon. If you think about it, you will understand why faster than I can type an explanationCan the open channel and emergency drains be combined into one pipe?

My sump is in my basement and a few rooms over so the less piping/connections the better.That presents it own set of problems for silent operation of the open channel... I.E. it makes it very hard to create a silent open channel that does not drop nearly staight down. You may be looking at a staight herbie with two dry emergency standpipes and hope it does not have to be fiddled with a lot.

The answer is pretty complicated, but it depends on the drop, pipe length and flow. It would be best to have it at the end of the run in your situation.The adjustment valve for the siphon branch. Can this be located just below the tank and maintain the silence with a long run of piping after it down to the basement?

Again, with your setup, it will be hard to tell. I would venture to say that you may have trouble with noise in the open channel. That much drop on a 1" siphon will help the flow, but the long horizontal will cause friction and turbulance. I use 1" thinwall for a lot of stuff, but don't think it is the right size for this project.And lastly, if im only planning on 1200gph max of return can I get away with using a 1" thin wall or 1 1/4" pipe for runs to the sump?

Which leads us right back to another debate I seem to recall, up sizing a notch to compensate for the reduced bore size.

Jim