I'm an acrylic guy so I can't answer that heh heh

What I can say is that if you build with the sides on top, that's opposite of the normal technique (for both acrylic and glass) where the front and back panels are on top of the end panels (the edges of the ends are bonded to the inside face of the front/back panel) so "extending the sides" becomes a constructability change, and you may not want to go there. If anything, on the front of your tank, you're going to see the end of the side panels, which is kinda ugly.

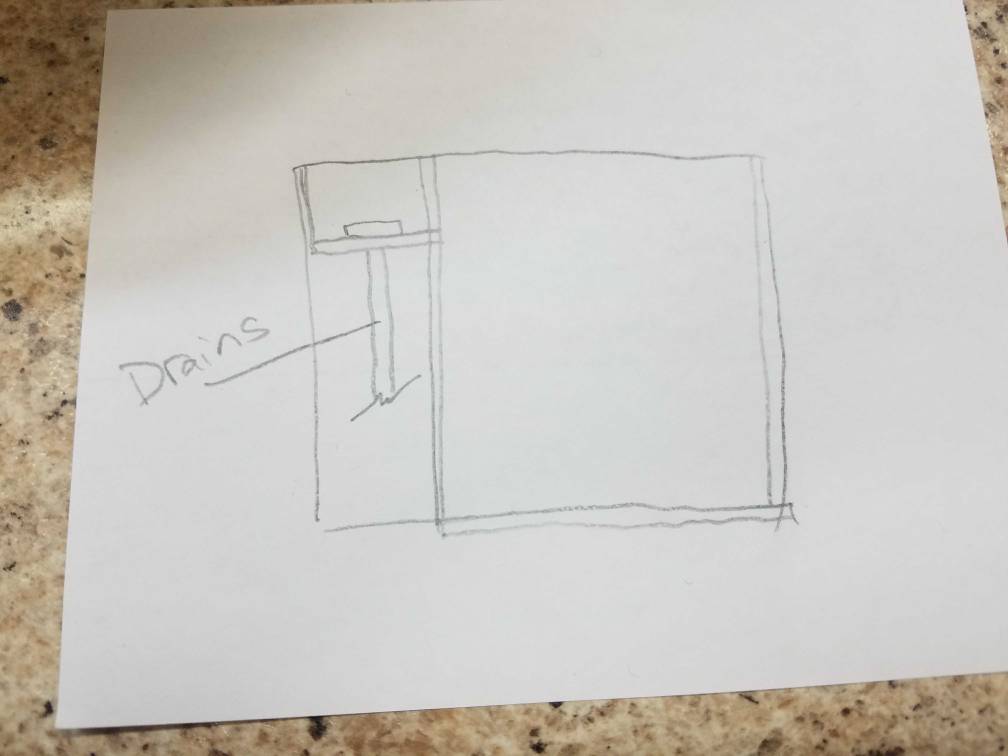

My personal advice would be to drill the back panel for pass-through holes and then use a very thin inside coast-to-coast and an outside box made of either glass or acrylic, and make those separate pieces. Basically either buy or make your own version of a Shadow or Ghost.

The reason I say this is because it allows for a lot of flexibility and allow you to correct something if you later realize that it doesn't work exactly the way you want it or envisioned it, or if you want to do something a bit different, etc. Making is part of the structure of the tank sounds great on paper but it also locks you into a solution and limits your ability to change.

Making a sturdy acrylic box and using bulkheads to hold it in place is a solid long-term solution. If you want some peace of mind, you can add in some kind of support method to take stress off the box and mitigate against any potential failure points (like weight of hanging off the back panel, if you're worried about that)

Cutting a notch in the top of the back panel or cutting teeth in the glass creates a huge amount of failure points. Lowering the height of the back panel relative to the sides would probably work, then add in a notched attachment or gutter guard etc, there's more than one way to do it, but I go back to the idea of building an overflow solution into the tank as having it's drawbacks...because I've done it.